Resinous coatings have revolutionized flooring options for Amarillo’s industrial and commercial properties. Property owners seeking durable and attractive floor finishes often turn to these robust solutions.

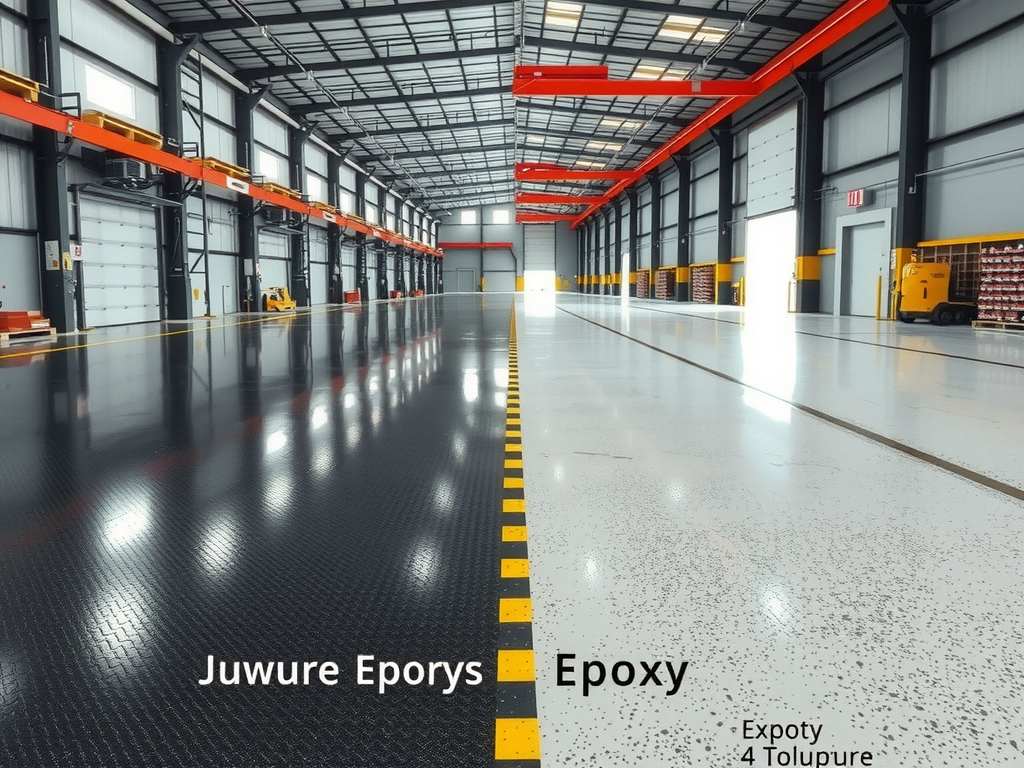

Epoxy and polyurea emerge as leading contenders, each offering unique benefits for various applications in the region’s diverse landscape.

Epoxy coatings are renowned for their exceptional chemical resistance and affordability.

These versatile solutions bond well with concrete substrates, providing a smooth, seamless surface that’s easy to clean.

Polyurea boasts rapid curing times and superior flexibility, making it ideal for areas subject to temperature fluctuations common in the local climate.

When selecting between these options, consider factors such as:.

- Durability and longevity

- Application process and curing time

- Resistance to chemicals and abrasion

- Cost-effectiveness

Evaluating these aspects will guide you towards a decision tailored to your specific needs in Amarillo’s unique environment. The choice between epoxy and polyurea depends on the particular requirements of your space and the conditions it must withstand.

Click here to learn more about: amarilloepoxyservices.com

Resinous Coatings: Epoxy Vs Polyurea

Industrial environments require robust flooring that can handle extreme conditions. Resinous materials have become top choices for heavy-duty protection in various settings.

These coatings provide exceptional strength and longevity, making them suitable for areas exposed to high impact and abrasion.

- Durability and Chemical Resistance:

- Epoxy provides excellent impact resistance and overall toughness

- Polyurea demonstrates superior flexibility and resistance to chemicals

- Both options offer enduring protection against wear

- Application Considerations:

- Epoxy generally needs more time to cure

- Polyurea can be applied across a broader temperature range

- UV-stable formulations exist for both coating types

- Cost Efficiency:

- Polyurea systems may require a higher upfront investment

- Epoxy often presents a lower initial cost

- Long-term upkeep expenses should be evaluated for both choices

Choosing between epoxy and polyurea coatings depends on specific industrial requirements, project schedules, and environmental factors. These elements are key for Amarillo businesses looking for long-lasting flooring solutions. The decision impacts not only immediate needs but also future maintenance and performance expectations. Companies must weigh the benefits of each option carefully to ensure they select the most appropriate coating for their unique operational demands and budget constraints.

Durable Solutions For Amarillo Businesses

Commercial entities in Amarillo seek resilient flooring options for their operations. Epoxy coatings emerge as a leading choice, delivering industrial-grade strength and longevity in high-traffic zones.

These solutions offer easy upkeep and cleaning, making them a cost-effective selection for facility management over time.

- Customization options:

- Color and design flexibility to match brand aesthetics

- Specialized coatings for specific industry requirements

- Texture options for improved safety and slip resistance

Key installation factors encompass proper surface preparation, optimal application methods, and minimizing operational disruptions during curing. Businesses in Amarillo reap temperature-resistant benefits such as:.

- Improved workplace safety and employee satisfaction

- Enhanced professional appearance for customer-facing areas

- Potential increase in property value

Epoxy flooring solutions strike a balance between durability and visual appeal, offering customized options for diverse business environments. These coatings provide antimicrobial properties, making them suitable for various industries. The solvent-free nature of many epoxy products aligns with eco-conscious business practices, while self-leveling formulations ensure a smooth, professional finish.

| Epoxy Flooring Benefits | Traditional Flooring |

|---|---|

| Industrial-grade strength and longevity | Shorter lifespan in high-traffic areas |

| Easy maintenance and cleaning | More frequent and intensive upkeep required |

| Customizable colors and designs | Limited design options |

| Antimicrobial properties | Potential for bacterial growth |

Chemical-Resistant Flooring Options Explained

Industrial spaces require robust surfaces to withstand harsh environments. Epoxy flooring systems excel in providing exceptional protection against corrosive substances.

These specialized surfaces are engineered to resist acids, solvents, and other damaging chemicals.

The nonporous nature of epoxy coatings creates a barrier that prevents substances from penetrating the underlying substrate.

Durable epoxy floors are ideal for facilities handling hazardous materials, offering long-lasting performance in challenging conditions.

The seamless application of epoxy flooring eliminates potential weak points where chemicals could seep through. This continuous surface not only enhances protection but also simplifies maintenance and cleaning procedures.

Epoxy’s stain-resistant properties make spill cleanup quick and efficient, reducing downtime in busy industrial settings. Beyond chemical resistance, these floors offer robust defense against thermal shock and heavy impact, ensuring a reliable surface for various operations.

- Resists acids, solvents, and corrosive chemicals

- Forms a protective, nonporous barrier

- Seamless application for enhanced safety

- Easy-to-clean and low-maintenance

For Amarillo businesses seeking durable solutions, chemical-resistant flooring offers peace of mind. The versatility of epoxy systems allows for customization to meet specific industry needs, whether in manufacturing, healthcare, or food processing. As we explore high-gloss and slip-resistant options, consider how these features can complement chemical resistance for optimal floor performance.

High-Gloss Or Slip-Resistant: Which

The selection of epoxy flooring finishes presents a pivotal choice for property owners and managers. Striking a balance between visual appeal and practical safety concerns requires careful consideration.

High-gloss epoxy coatings offer a stunning sheen that enhances light reflection and creates an impressive aesthetic.

These surfaces are relatively easy to maintain and provide a smooth, seamless look.

In areas prone to moisture or spills, the glossy finish may increase the risk of slipping.

Slip-resistant epoxy alternatives incorporate textured additives to improve traction and reduce accidents.

While these surfaces may not have the same lustrous appearance as their high-gloss counterparts, they significantly enhance safety in wet conditions. The chemical bonding between the epoxy and textured particles ensures long-lasting slip resistance.

- High-gloss advantages: Sleek appearance, simple cleaning, excellent light reflection

- Slip-resistant benefits: Enhanced safety, improved grip in wet areas

Many professionals recommend a strategic combination of both finishes to optimize functionality and aesthetics. For example, applying slip-resistant coatings in high-traffic zones or areas exposed to moisture, while reserving high-gloss finishes for showcase spaces or low-risk environments. This approach allows for a customized solution that addresses specific needs throughout a facility.

The decision between high-gloss and slip-resistant epoxy finishes should be based on a thorough assessment of each area’s requirements. Factors to consider include foot traffic patterns, exposure to liquids, lighting conditions, and overall design goals. Consulting with experienced epoxy flooring specialists can help determine the most suitable finish for each space.

Proper substrate preparation is essential for ensuring optimal adhesion and longevity of the chosen epoxy finish. This step is particularly important when transitioning from chemical-resistant flooring options to areas that require either high-gloss or slip-resistant surfaces. The seamless application process of epoxy coatings allows for a smooth integration of different finishes within a single facility.

Key Points About Epoxy Flooring Finishes

- High-gloss epoxy coatings enhance light reflection and create a seamless look

- Slip-resistant epoxy incorporates textured additives to improve traction

- Combining both finishes allows for customized solutions in different areas

- Proper substrate preparation is crucial for optimal adhesion and longevity

Seamless Application Process Unveiled

Expert technicians employ a meticulous approach to achieve flawless results in epoxy flooring applications. The process begins with thorough surface preparation, often involving grinding or shot blasting to ensure optimal adhesion.

A specially formulated primer enhances bonding and is allowed to cure before the next step.

Skilled professionals then mix and apply the epoxy base coat evenly, incorporating reflective color flakes or aggregates for added texture and aesthetics.

For enhanced durability or decorative effects, additional intermediate layers may be applied.

The final clear top coat provides extra shine and chemical resistance, offering corrosion protection and sealing the entire system. After application, the floor undergoes a crucial curing period.

Experts conduct a quality check to ensure perfection in the finished product, which can be customized with skid-resistant additives or static dissipative properties depending on specific requirements.

Key aspects of the epoxy flooring process:

- Thorough surface preparation ensures long-lasting results

- Multiple layers contribute to durability and aesthetic appeal

- The curing process is vital for optimal performance

Impact-Resistant Flooring Cost Estimates

Durability comes at a price, but smart investments yield long-term benefits. Evaluating the financial aspects of robust flooring solutions requires careful consideration of multiple factors.

Floor preparation, system selection, square footage, and project complexity all influence the final expenditure.

Impact absorption capabilities play a crucial role in determining the overall value of these specialized surfaces.

Basic epoxy systems offer moderate durability, ranging from $3 to $7 per square foot.

Advanced hybrid solutions, boasting enhanced load-bearing properties, typically cost between $7 and $12 per square foot. High-end options with superior thermal cycling resistance can exceed $15 per square foot, delivering exceptional longevity and performance.

- Customization options: May increase costs by 10-30%

- Maintenance requirements: Generally low, contributing to long-term savings

- Rapid return-to-service: Minimizes operational disruptions, offsetting initial expenses

Comparing these specialized floors to traditional alternatives reveals significant advantages over time. While the upfront investment might be higher, reduced maintenance needs and extended lifespan often result in favorable returns, particularly for high-traffic commercial properties. The solids content of these systems contributes to their resilience and longevity, justifying the initial cost.

| Basic Epoxy Systems | Advanced Hybrid Solutions | High-End Options |

|---|---|---|

| $3 – $7 per square foot | $7 – $12 per square foot | $15+ per square foot |

| Moderate durability | Enhanced load-bearing properties | Superior thermal cycling resistance |

| Cost-effective option | Balanced performance and price | Exceptional longevity and performance |

UV-Stable Coatings For Outdoor Spaces

Innovative solutions for exterior surfaces offer exceptional durability against harsh sunlight. These advanced formulations provide long-lasting protection, ensuring vibrant colors and structural integrity remain intact.

Epoxy-based products excel in this regard, delivering superior performance for various outdoor applications.

Shore hardness ratings demonstrate their resilience against wear and tear, making them ideal for high-traffic areas.

Garages, patios, and pool decks benefit significantly from these robust coatings. The quick-curing systems minimize downtime during installation, allowing for rapid project completion.

Eco-conscious homeowners appreciate the low-maintenance aspects of these finishes, reducing the need for frequent recoats. Window frames and other exposed elements also gain extended lifespans when treated with these specialized products.

Cost-effectiveness is another advantage of UV-resistant coatings.

While initial investments may be higher than traditional paints, the long-term savings in repair and replacement costs are substantial.

Adhesion testing ensures proper bonding to various substrates, guaranteeing optimal performance across different materials and surfaces.

Quick-Curing Systems: Installation Time

Advanced flooring technologies have transformed the industry, allowing for swift project completion with minimal interruptions. These innovative systems offer remarkable advantages, significantly reducing downtime compared to conventional options.

Surface profile considerations are essential for achieving optimal adhesion and durability of these cutting-edge coatings.

- Installation Time Comparison:

Conventional epoxy: 3-7 days

Fast-curing systems: 4-24 hours - Factors Influencing Speed:

Temperature, humidity, coating thickness - Sector Benefits:

Industrial: Limited production delays

Commercial: Swift store re-openings

Residential: Decreased inconvenience for homeowners

Companies can enhance efficiency by strategically scheduling installations and choosing suitable fast-curing systems for their unique requirements. Professional application ensures optimal results and long-lasting performance. Proper mixing ratios and application techniques contribute to the overall success of these advanced flooring solutions.

Key Points About Advanced Flooring Technologies

- Fast-curing systems can reduce installation time from 3-7 days to just 4-24 hours

- Temperature, humidity, and coating thickness influence the speed of installation

- Different sectors benefit from reduced downtime, including industrial, commercial, and residential

- Proper mixing ratios and application techniques are crucial for optimal results and longevity

Polyaspartic Garage Floor Experts Transform Amarillo Spaces

Amarillo Flooring Contractor Transforms Spaces With Epoxy Solutions